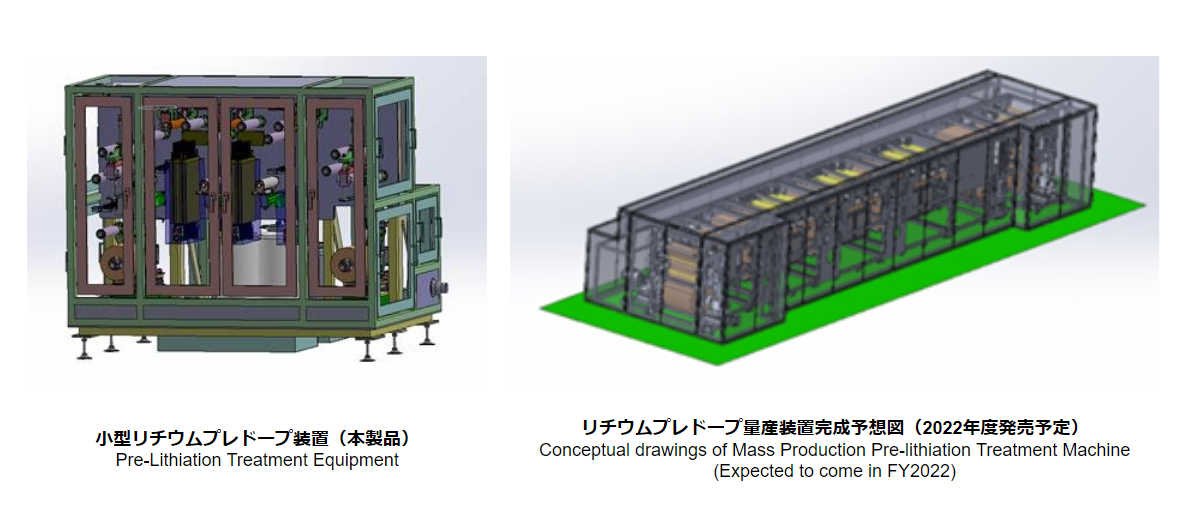

预锂化处理设备 Pre-lithiation Treatment Equipment

本产品采用卷对卷方式预嵌锂(锂均匀进入电极),以增加锂离子二次电池(以下简称锂离子电池)的容量、延长寿命和安全性。离子电池。它是一个装置(插入)。

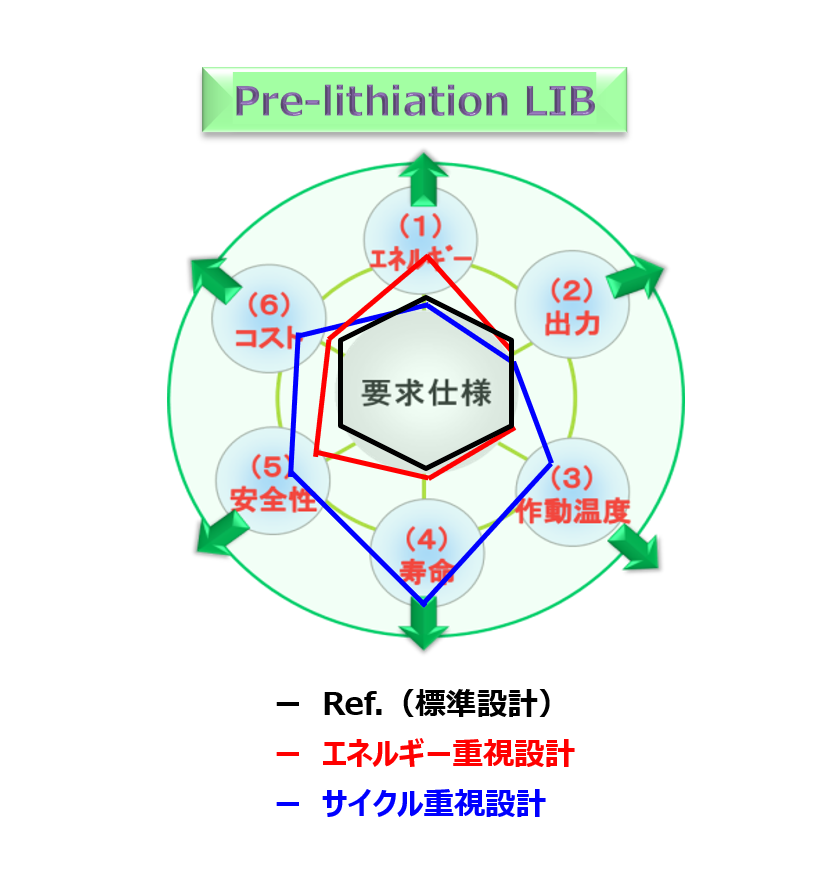

锂预嵌入技术可在考虑锂离子电池正负极容量平衡的情况下实现高效的电池设计,并且众所周知可有效提高和区分锂离子电池的性能。

Pre-lithiation Treatment Equipment

Product Information

This product is pre-doping (uniform Lithium inserting into electrode) equipment by the roll-to-roll method, aiming increased capacity, extending life, and improve safety of Lithium-ion secondary batteries (hereinafter referred as lithium-ion batteries or LIB).

-

- Lithium predoping technology enables efficient cell design considering the capacity balance of the positive and negative electrodes of lithium-ion batteries, and is widely known to be effective in improving and differentiating the performance of lithium-ion batteries.

Product Features

This machine is a pre-doping facility that enables battery design and battery development that meets customer needs, such as higher capacity, longer life, and improved safety, using the roll electrodes of existing lithium-ion batteries as they are.

- Small operating load (operator, consumables, etc.) enables production of small amount and many variety samples.

- It is possible to accelerate the development speed of lithium-ion batteries to which pre-lithiation is applied from the viewpoints of cell design verification, active material screening, electrode composition examination, etc.

- It is possible to pre-lithiation the electrodes for large cells at the product level, and it is possible to study the optimization of process conditions in anticipation of the introduction of mass production equipment.

Product Innovation

Until now, it has been considered difficult at the industrial level to uniformly add a predetermined amount of lithium to the inside of the electrode (inside the active material).

In order to achieve this, it is necessary to combine advanced expertise and technology in "chemical reaction: chemical", "electrochemistry: electrical", and "transport equipment: mechanical".

This time, by combining the chemical, electrochemical, and mechanical technologies that we have cultivated so far, and forming a partner with CKD Corporation, which has a proven track record in electrode transfer technology for winders, etc., it was an industrial level that was difficult in the past. We were able to develop a roll-to-roll lithium pre-doping device. This makes it possible to consider the introduction of pre-dope in the development and manufacturing process of lithium-ion batteries.

Why pre-dope is attracting attention

The first appearance of energy storage devices using the pre-lithiation technology also provided this equipment was around 2005. However at that time, pre-lithiation was realized by using porous current collectors as electrodes, the "lithium foil" and "negative electrode"placed in a same cell were connected together, and electrolyte injected to start doping.

However, at that time, the use of this porous current collector was limited, and there was a problem that the manufacturing cost was high. Therefore, at that time, in the lithium-ion battery market, where price competition was fierce, the introduction of pre-doping technology, which requires additional costs, was not considered in earnest.

On the other hand, in recent years, in the lithium-ion battery market, not only simple price competition but also differentiation in terms of performance has been emphasized. Under these circumstances, pre-doping technology, which realizes higher capacity, longer life, and improved safety of lithium-ion batteries, is attracting attention again.

In particular, the method used by this machine that uniformly inserts a predetermined amount of lithium electrochemically is considered to further improve the performance of lithium-ion batteries, and lithium-ion battery manufacturers and future mass production are also in view. It is attracting a lot of attention from electric vehicle manufacturers that use battery technology and advanced consumer product manufacturers.

Benefits of pre-doping technology

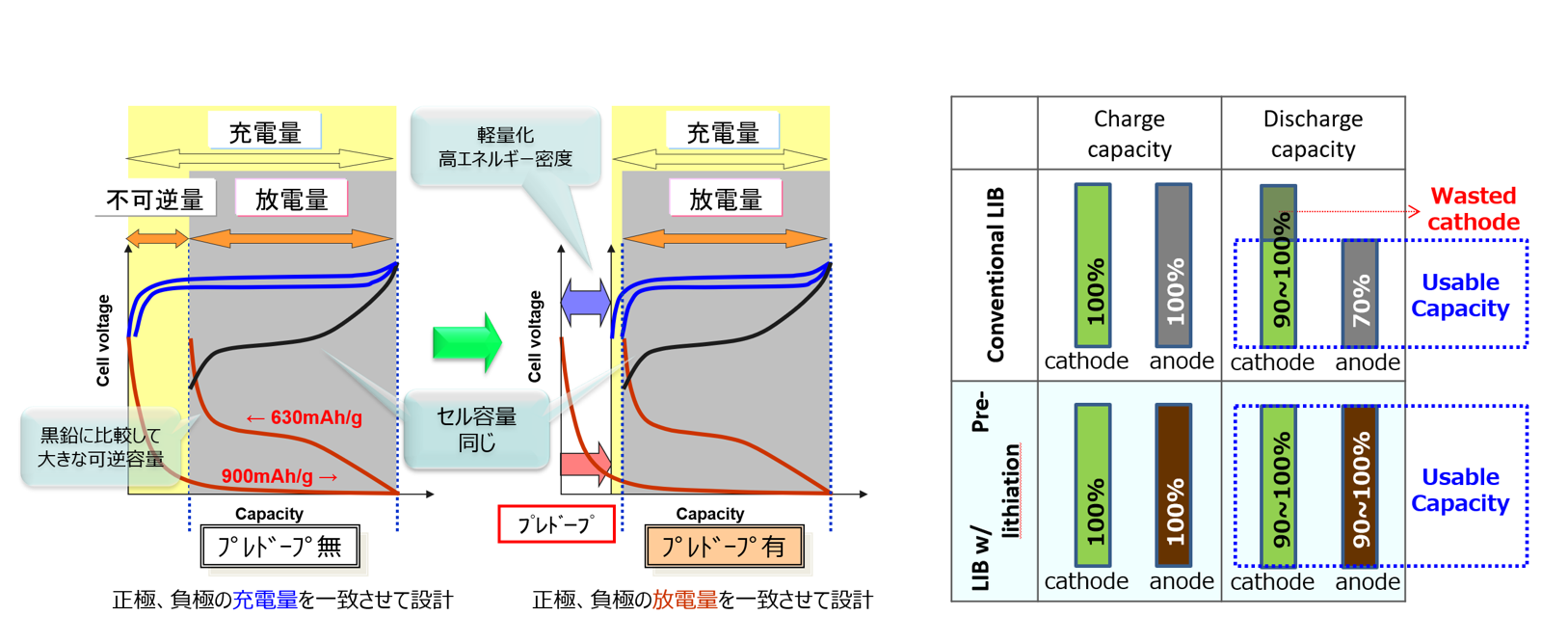

-

- The introduction of pre-lithiation technology makes it possible to reduce the amount of expensive rare metals used as the positive electrode material for lithium-ion batteries.

- Depending on the design, lithium pre-doping into the lithium-ion battery can improve the energy density by about 20% to 40% and extend the cycle life of the lithium-ion battery by about 3 to 4 times.

(Conceptual diagram) Energy density improvement by reducing irreversible capacity

(Conceptual diagram) Energy density improvement by reducing irreversible capacity

Target industry / manufacturer

- Lithium-ion battery manufacturers who want to differentiate their battery performance from other companies

- EV manufacturers / advanced consumer product manufacturers who require advanced control technology for lithium-ion battery characteristics